Green Hydrogen - simple, safe and efficient.

We support electrolyser OEMs in simplifying system designs with integrated fluid control solutions. So you can focus on what matters - scaling up green hydrogen.

We support electrolyser OEMs in simplifying system designs with integrated fluid control solutions. So you can focus on what matters - scaling up green hydrogen.

Say goodbye to hours wasted on sizing the right fluid control solutions. And the hassle that comes with assembling parts that don't play well together.

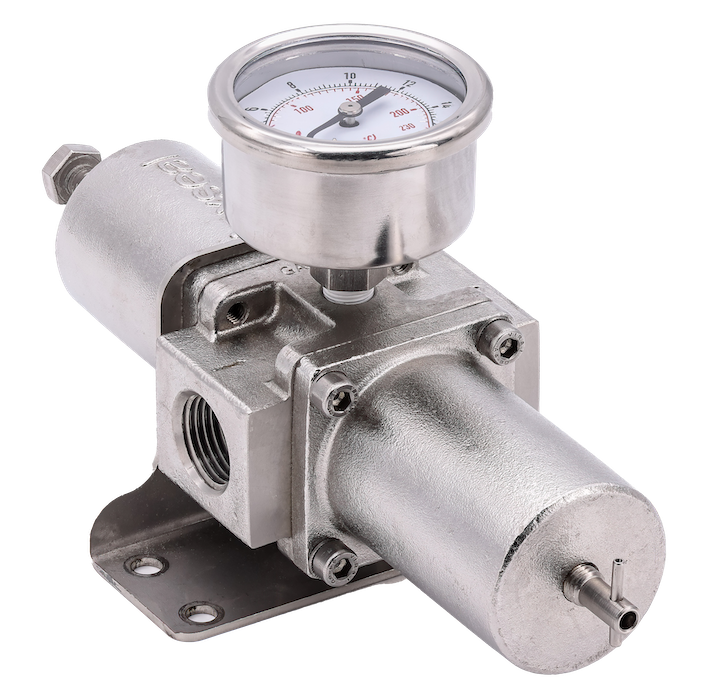

Too much pipework? Many potential leak points? A high component count? Take the complexity out of your electrolyser balance of plant with integrated manifold solutions. Designed for use in hydrogen and oxygen loops.

Modular functionality

Easy to service

Plug & play

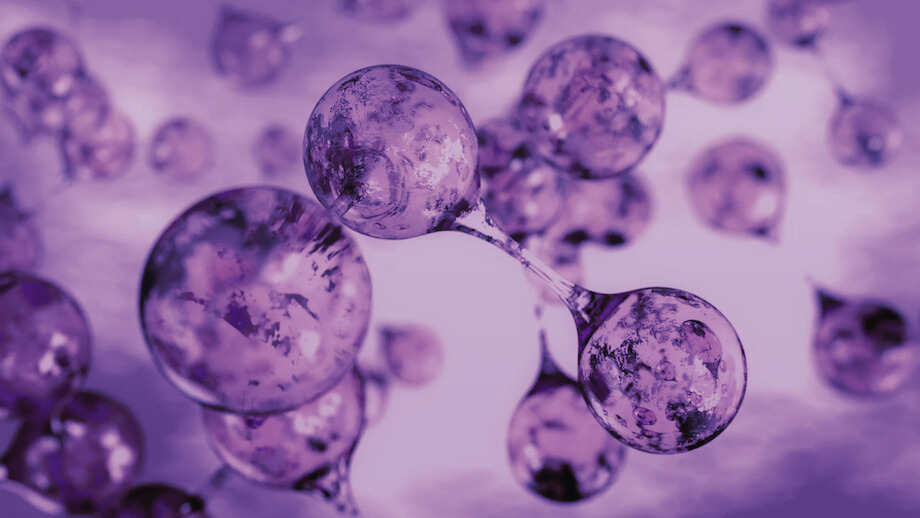

No matter if backpressure tight solenoid valves or high-precision regulators - we’ve got you covered. Our solutions help you solve the most common challenges in electrolyser designs, such as gas mixing in the seperator unit.

Highest grade materials

Globally certified and approved

Our solutions are battle proof and have seen millions of hours in operation.

Our three-stage process to simplify your system design

An easy and efficient way to identify the best solution for your application. By working with our team of hydrogen experts, you'll avoid wasting time with multiple suppliers.

We review your P&ID together with you and identify key improvement areas.

Our experts develop a custom solution concept based on your P&ID.

Getting physical - time to test the actual solution in your system.

Learn about our solutions to reduce complexity in your electrolyzer balance of plant.

By submitting your details you agree to IMI's Privacy Policy and Terms and Conditions.

“We have had great experience with IMI and the service we have had from IMI has been second to none. We have really appreciated the collaborative approach to problem solving when we are working on a new product development.”

We are a team of electrolysis specialists. Our goal is to advance the rollout of green hydrogen by solving the biggest fluid control problems in the electrolysis industry.

Business Development Manager

Andrea has many years of experience as an advisor to leading electrolyzer OEMs. He supports them in developing efficient, reliable, and safe electrolysis systems.

Engineering Director

Michael leads our hydrogen engineering team. His objective: designing, testing and continuously improving the best fluid control solutions for hydrogen applications.

Global Hydrogen Director

Darran has held various leadership roles in the hydrogen space. From production to refuelling, he supports our customers with a holistic view on the value chain.

Program Manager

As program manager, Welf ensures the perfect fit between product development and our customers’ requirements. The right solutions at the right time.

Complexity drives up both operational expenditures (OpEx) and capital expenditures (CapEx), ultimately driving up the cost of the hydrogen produced. If we want to get electrolysis right, we need to focus on simplification.

Invest your resources in what really matters by simplifying your design.

Increase overall safety levels in your system by reducing leakage points.

A simpler design is not only safer. It is also much easier to maintain.

Improve the overall footprint of your system so you scale up faster.

On the call, we’ll review your current setup and requirements. We’ll then identify improvement areas and determine if it’s a good fit for both of us.